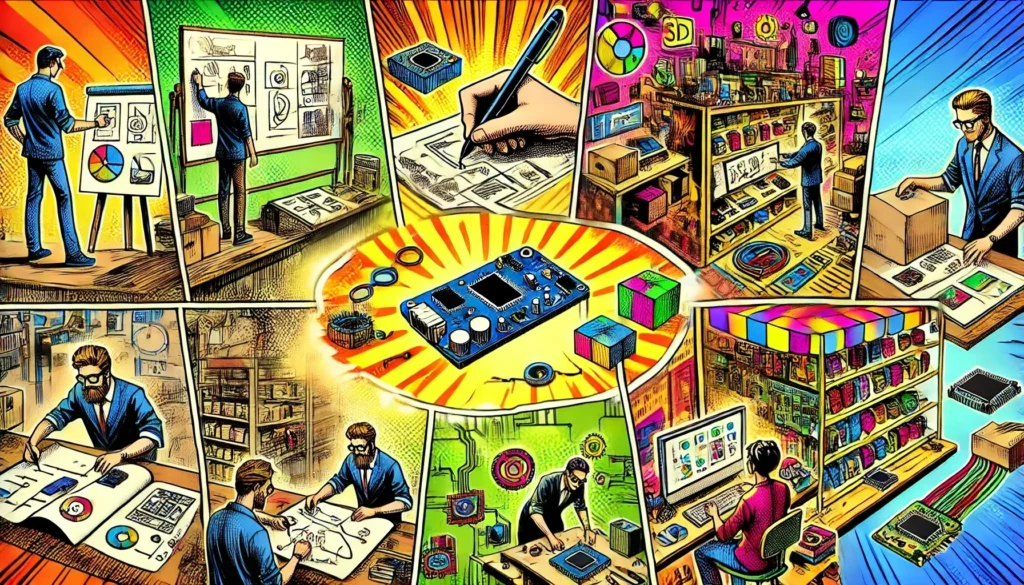

Creating an electronic product – from the initial concept to seeing it on store shelves – is an intricate process that involves multiple stages, each with its own set of challenges, decisions, and creative input. The journey from drawing board to market requires not only technical expertise but also a solid understanding of design, testing, manufacturing, and marketing.

In this guide, we’ll walk through the lifecycle of an electronic product, covering each key stage from concept to consumer, and highlight the considerations that go into building a successful product.

Table of Contents

5. Production and Quality Control

8. Post-Launch Support and Iteration

Final Thoughts: From Drawing Board to Reality

1. Concept and Planning

Every product begins with an idea. In the concept and planning stage, teams brainstorm and outline the product’s purpose, features, target audience, and value proposition. This stage is crucial for defining the market need and ensuring that the concept aligns with customer expectations and business goals.

Key Steps in the Concept Stage:

- Identify Market Needs: Conduct research to understand what gaps exist in the market and what consumers are looking for. Determine how your product will meet these needs better than existing options.

- Define Product Specifications: Outline the basic functionality, user interface, power requirements, connectivity, and other technical specifications.

- Set a Budget and Timeline: Develop an initial budget and timeline to guide the project. Early estimates will help determine the feasibility and potential profitability of the product.

Example: A tech startup identifies the need for a compact, easy-to-use air quality monitor for urban homes, aiming to make air quality data accessible through a smartphone app.

2. Design and Prototyping

Once the concept is refined, the next step is to translate it into a tangible design. In this stage, engineers and designers work together to create a blueprint of the product, from the internal circuitry to the outer casing. Prototyping allows for early testing and iteration, ensuring the product performs as intended.

Key Steps in Design and Prototyping:

- Electronic Circuit Design: Engineers design the circuits, including component selection, schematic creation, and layout design. This stage also involves creating a Bill of Materials (BOM) listing all components required for manufacturing.

- Mechanical Design: Designers create 3D models for the casing and physical structure of the product, ensuring it’s user-friendly and visually appealing.

- Prototyping: Engineers create a working model using methods like 3D printing for the casing or PCB fabrication for the circuit board. Prototyping allows for testing and tweaking to address design flaws or improve performance.

Example: A prototype of the air quality monitor is created with a custom PCB that includes sensors to measure particulate matter, VOCs, and CO2, and a 3D-printed case for testing the product’s physical design.

3. Testing and Validation

Testing is an essential phase where the prototype undergoes rigorous assessments to ensure it meets quality, safety, and performance standards. Validation ensures that the product is both functional and reliable under various conditions.

Key Steps in Testing and Validation:

- Functional Testing: Verifies that each component and feature works as expected. For an electronic product, this may include testing power efficiency, signal integrity, and component stability.

- Compliance Testing: Ensures the product meets industry standards and regulatory requirements, such as FCC certification for wireless products or CE marking in Europe.

- Environmental and Stress Testing: Assesses durability by exposing the product to various conditions, including temperature extremes, humidity, and physical impact.

- User Testing: Involves real users testing the product to provide feedback on usability, design, and functionality, leading to refinements based on their experiences.

Example: The air quality monitor undergoes compliance testing for wireless communication standards and environmental testing to ensure accuracy and durability in various climates.

4. Manufacturing Preparation

With a validated design, the focus shifts to preparing for mass production. This stage involves finalizing the product’s specifications, setting up a supply chain for components, and ensuring that manufacturing processes are efficient, cost-effective, and scalable.

Key Steps in Manufacturing Preparation:

- Design for Manufacturability (DFM): Engineers refine the design to optimize it for manufacturing, minimizing complexity and costs while maintaining quality.

- Supplier Selection and Procurement: Identify suppliers for components, materials, and packaging. Build relationships with reliable suppliers to ensure timely delivery of high-quality parts.

- Tooling and Equipment Setup: Prepare tooling (such as injection moulds for plastic casings) and assembly line equipment necessary for production.

Example: The air quality monitor design is finalized to simplify assembly and reduce material costs. The team partners with a reputable PCB supplier and a factory specializing in electronic assembly.

5. Production and Quality Control

The production phase is when the product is manufactured in bulk, involving assembly, testing, and quality assurance on a large scale. Ensuring consistent quality during production is essential to maintain brand reputation and customer satisfaction.

Key Steps in Production and Quality Control:

- Assembly Line Setup: Manufacturers set up an assembly line with stations for each step, from PCB assembly and soldering to final assembly and packaging.

- Quality Control and Inspections: Quality control teams conduct inspections to check for defects or inconsistencies, using sampling and automated testing to ensure each unit meets standards.

- Batch Testing: Select a batch of finished products for additional testing to verify that all units meet specifications and are free from defects.

Example: During production of the air quality monitor, quality control teams randomly sample devices to test sensor accuracy, Wi-Fi connectivity, and battery performance, ensuring each device performs as expected.

6. Packaging and Distribution

Packaging is often the first impression customers have of a product, so it must be both attractive and functional. After packaging, the product is shipped to distributors or retailers for sale, with logistics and inventory management playing a key role.

Key Steps in Packaging and Distribution:

- Packaging Design: Create packaging that protects the product during shipping, while also being visually appealing and informative for the customer.

- Distribution Strategy: Determine the best way to get the product to customers, whether through retail stores, online sales, or a mix of both.

- Inventory Management: Implement systems to track inventory, manage reorders, and ensure product availability to avoid stockouts.

Example: The air quality monitor is packaged in eco-friendly materials that highlight its benefits, with distribution channels set up for both e-commerce and retail outlets.

7. Marketing and Launch

With the product ready to reach customers, a successful launch and marketing strategy are crucial. Marketing not only introduces the product but also highlights its unique features and value proposition to attract the target audience.

Key Steps in Marketing and Launch:

- Branding and Positioning: Develop a clear brand identity and product messaging to differentiate it from competitors and resonate with customers.

- Marketing Campaigns: Use digital ads, social media, and content marketing to generate awareness and interest. Engage early adopters and influencers to build credibility and excitement.

- Launch Events: For high-impact launches, consider hosting events or webinars to introduce the product to key stakeholders, partners, and press.

Example: The air quality monitor is launched with a digital campaign targeting eco-conscious consumers, featuring testimonials, influencer endorsements, and educational content about air quality and health.

8. Post-Launch Support and Iteration

Once the product is on the market, the focus shifts to customer support and product improvements. Gathering feedback from users is essential to address any issues, provide updates, and plan for future iterations or upgrades.

Key Steps in Post-Launch Support and Iteration:

- Customer Support: Establish a support system to help customers with setup, troubleshooting, and repairs, and offer prompt assistance to build brand loyalty.

- Feedback Collection: Gather feedback from customers through surveys, reviews, and direct interactions to identify strengths and areas for improvement.

- Product Updates and Iterations: Use feedback to guide improvements, whether through software updates, hardware tweaks, or new feature rollouts for future models.

Example: After the launch, the air quality monitor team gathers feedback, leading to a firmware update to improve app connectivity and discussions on adding a Bluetooth feature for future versions.

Final Thoughts: From Drawing Board to Reality

Creating an electronic product involves a comprehensive journey from conceptualization to consumer. By carefully navigating each stage – concept, design, testing, manufacturing, marketing, and support – engineers, designers, and marketers work together to bring innovative ideas to life. This process requires a balance of creativity, technical skill, and business acumen to build a product that meets user needs and succeeds in the market.

Curious about diving deeper into the stages of product development? Explore our blog for tips, case studies, and resources on design, manufacturing, and marketing. Don’t forget to subscribe for insights into the latest trends in electronics and product innovation!